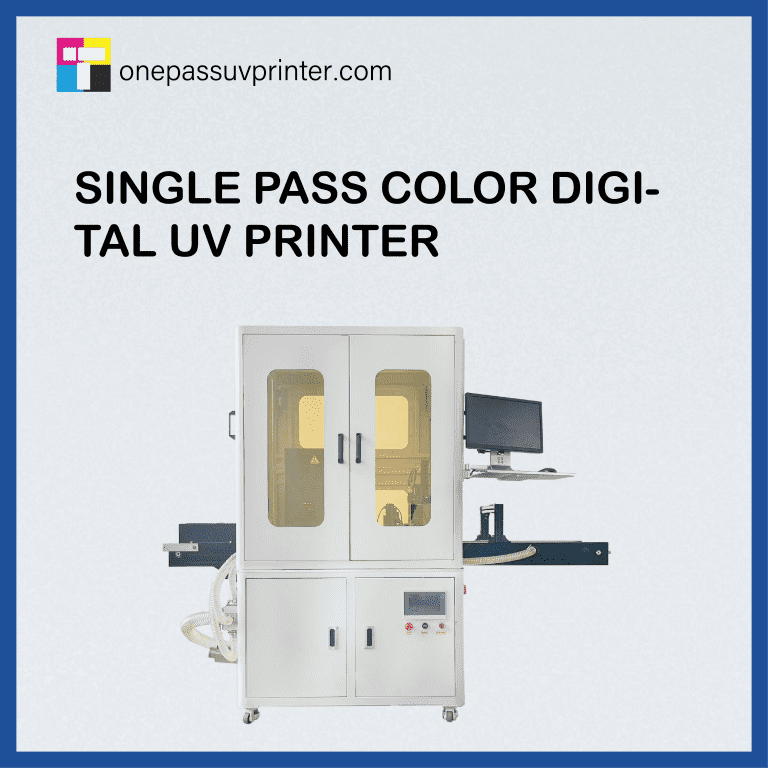

next generation printing platformversatile digital printer for variable data printing customized

Print production industry is experiencing a paradigm change driven by new one-pass UV innovations. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. By harnessing UV light to cure inks on contact, single-pass UV printing negates long drying periods and repeat passes, decreasing production cost and cycle time.A central benefit is its capacity to render vibrant, lasting images across various substrates including plastic, metal, and cloth. Top-tier resolution in single-pass UV generates precise image and typographic detail, excellent for packaging, signage, and marketing items. Also, this environmentally conscious tech consumes less energy than traditional printing, helping make production more sustainable.

Print production industry is experiencing a paradigm change driven by new one-pass UV innovations. This state-of-the-art technique facilitates fast runs and consistent, long-lasting print quality. By harnessing UV light to cure inks on contact, single-pass UV printing negates long drying periods and repeat passes, decreasing production cost and cycle time.A central benefit is its capacity to render vibrant, lasting images across various substrates including plastic, metal, and cloth. Top-tier resolution in single-pass UV generates precise image and typographic detail, excellent for packaging, signage, and marketing items. Also, this environmentally conscious tech consumes less energy than traditional printing, helping make production more sustainable. The rollout of single-pass UV opens novel opportunities for companies to elevate printing capabilities.

The rollout of single-pass UV opens novel opportunities for companies to elevate printing capabilities. Single-Pass UV Trends

Digital high-speed printing historically pursues efficiency. Formerly this involved successive ink passes, increasing lead time and alignment errors. Still, the emergence of Single-Pass UV is shifting the market. The technology employs UV curing in one pass to instantly set inks, yielding major speed and precision boosts.Single-Pass UV renders lively colors with incredible clarity and depth of detail. Hence it’s perfect for applications such as mass packaging, outdoor billboards, and marketing collateral where quickness and impact are critical. As advances continue, single-pass UV promises more revolutionary gains toward fast, flexible, and cost-efficient printing.

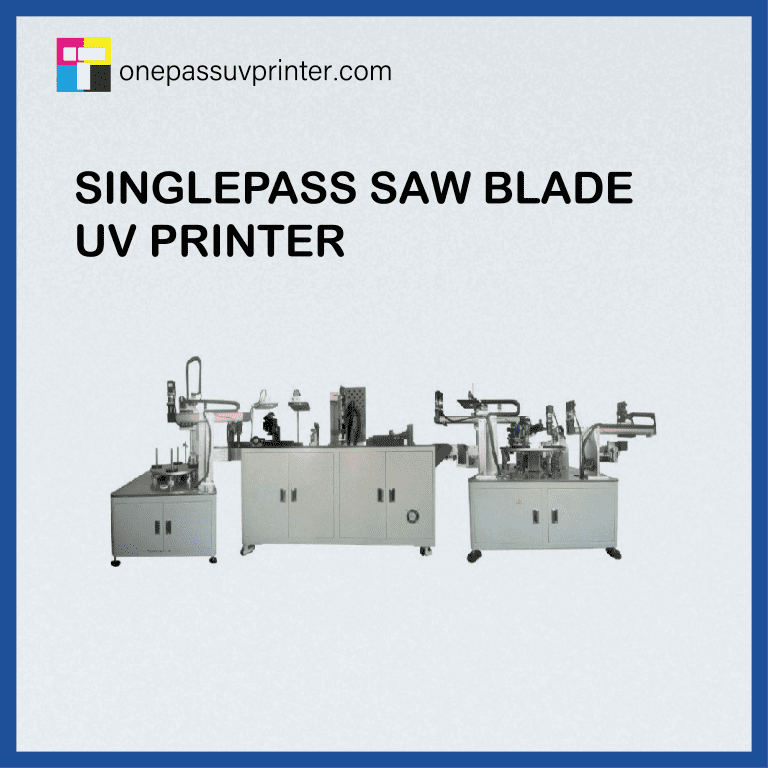

Single-Pass UV Printers: Speed Meets Accuracy

Within the printing industry, single-pass UV printers have surfaced as pivotal innovations elevating speed, exactness, and production efficiency. These platforms leverage UV curing to immediately fix inks, unlocking remarkable output rates. By executing multiple colors in one pass, these printers produce exceptional clarity and vibrant color profiles. From custom short runs to mass commercial production, they support diverse applications, helping companies meet growing market needs.Transform Your Printing Workflow

Expect to be impressed by the single-pass UV printer — a strong solution transforming industry norms. This clever device leverages UV light to fix inks in one pass, attaining remarkable quality and resolution.- Experience vibrant colors with unparalleled precision

- Maximize output using accelerated print functions

- Access expanded creative options with many printable materials

Express UV Printing: Delivering Unmatched Efficiency

UV printing has changed the graphics landscape through faster production, precision, and strong color reproduction. Still, speed-optimized UV printing enhances these strengths, offering unprecedented production efficiency. This system uses specialized equipment that outputs high-res images at very quick rates. Thanks to instantaneous curing and minimal dry time, rapid UV printing optimizes processes enabling easy fulfillment of demanding jobs. High-speed UV’s benefits also encompass quality enhancements in addition to efficiency. It achieves remarkable print excellence, resilience, and suitability for many applications. From packaging through banner and label production to promotional signage, fast UV printing remodels business operations for innovation and agility.

One-Pass Workflow: The Ultimate Solution for Fast Turnaround Times

In contemporary commerce, speed is essential. For print production, fast and efficient systems are essential. One-Pass Print addresses this need. It enables single-pass printing to avoid multiple runs and shorten total processing time. One-Pass Print offers dramatically quicker turnaround times, recovering valuable time and capacity. Therefore, organizations across sizes can leverage One-Pass Print advantages. From promotional prints to required documents, it supports immediate printing with no trade-offs.Quality and Velocity Combined in Single-Pass UV

In current manufacturing contexts, efficiency is top priority. Producers need systems that preserve quality and sustain speed. Single-pass UV appears as a breakthrough merging fine inspection with instant curing. This technique applies ultraviolet curing for inks and coatings, yielding lively, resilient finishes with reduced production time. The precise nature of single-pass UV assures flawless production that reaches strict quality criteria. Benefits expand beyond improved speed and fidelity. Single-pass UV cuts waste by removing long drying periods, aiding sustainable manufacturing.- Additionally, Single-Pass UV’s adaptability supports industries ranging from packaging and graphics to electronic assembly.

Innovating Digital Printing with High-Speed UV

The industry moves forward constantly, urged by ongoing needs for faster speeds, better precision, and inventive approaches. Rapid UV tech has surfaced as a transformative force combining these crucial elements. Ultraviolet curing in UV printing sets inks instantly, avoiding slow drying and enabling new printing possibilities. This rapid curing process allows for exceptional print speeds, significantly reducing production time and boosting overall efficiency. Besides, UV inks provide excellent durability and protection from fading, abrasion, and water, making them broadly applicable. From engaging displays to robust packaging, high-speed UV printing is transforming print production.- Merits

The Age of Immediate Photos: UV Printing in Action

Within rapid graphics and design markets, time holds great value. Clients seek rapid delivery, and businesses must offer high-quality prints swiftly. Enter one-pass UV printers, supplying disruptive solutions for today’s printing challenges. Such advanced devices utilize ultraviolet inks that harden instantly under light, eliminating long drying cycles. The payoff: immediate prints with bold colors and long-lasting finishes. As such, single-pass UV printers apply to many different industries. From retail, e-commerce, and marketing through photography, fine art, and manufacturing, businesses embrace immediate printing. Applications include creating personalized products, producing custom signage, and generating eye-catching marketing materials. The advantages extend beyond speed and efficiency. Single-pass UV units also provide superb color fidelity, high resolution, and broad material compatibility for challenging projects.- Furthermore, single-pass UV is sustainable because it uses no harsh solvents or VOCs.

- To summarize, instant-print technology is established: with speed and versatility, one-pass UV is altering printing toward greater efficiency.

Modernize Your Workflow with Single-Pass UV

Tighten production process and realize greater efficiency via single-pass UV printing. The technology allows printing crisp, colorful high-res images onto diverse substrates in a single pass without digital printer layered stages.- Experience unparalleled speed and reduce production times.

- Expand production capacity with faster fulfillment.

- Use UV ink’s durable precision to secure long-lasting vibrant prints.

Single-Pass UV: Boosting High-Impact Print

Single-pass UV emerges as a pivotal development in high-impact printing. Using UV to cure ink instantly, this method brings significant advantages beyond traditional processes. Primarily, single-pass UV delivers unmatched image fidelity with vivid colors and sharp detail. Instant UV cure erases drying delays, improving productivity and cutting turnaround time.- Additionally, single-pass UV yields durable prints resistant to fade, scratch, and abrasion.

- In conclusion, the combination of exceptional image quality, increased productivity, and durability makes single-pass UV printing a compelling choice for businesses seeking high-impact printing solutions.